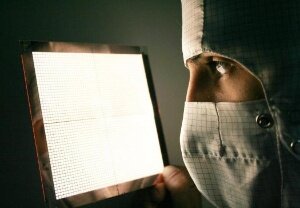

OLED stands for Organic Light Emitting Diode and within the context of displays this means that the panel is made of layers of organic material, such as carbon. Modern OLED designs do not need any backlighting and effectively light themselves, unlike current LCD/LED monitors. This results in much thinner and more energy efficient products. OLED displays use an electron-emitting cathode that can be fitted around the screen rather than directly behind it, a design that calls for less power consumption than active backlighting. The biggest benefits of OLED technology are screens that are literally wafer-thin, consume almost no energy (and therefore do not heat up), and in the future may even be made fully bendable and stretchable.

Displays made using OLED fabrication manage even better, crisper, and more vibrant image quality than LCD and standard LED screens, and have fast response times, which is great for gaming and movie watching, plus wider viewing angles. Which is splendid for everything, really.

The materials applied in OLED screens are categorised in several ways. Small molecule OLED (SM-OLED) offer great image quality, but they’re evaporable and therefore have a shorter lifespan than polymer OLED materials (P-OLED). The latter are also known as large molecule OLED, they last longer than SM-OLED materials and can be fabricated using more diverse methods. However, the image quality and application diversity they support is limited compared to SM-OLED.

Within these two materials can also be divided into fluorescent and phosphorescent. The former are more resilient and offer a longer product lifespan, but again, need more energy to work. Phosphorescent materials are more efficient, but less durable.

Active vs. passive OLED

Passive matrix OLED displays, or PMOLEDs, use basic electron projection to generate images. While very energy conserving, these screens lack the power needed to support high resolutions on large panels. That’s where active matrix OLED (AMOLED) panels come in. These incorporate elements from current monitor technology such as capacitors and a TFT array, though in miniaturized form to reduce product thickness/depth. They consume more energy, but can be placed in large format displays and support extremely high resolutions, which is what the future needs, obviously.

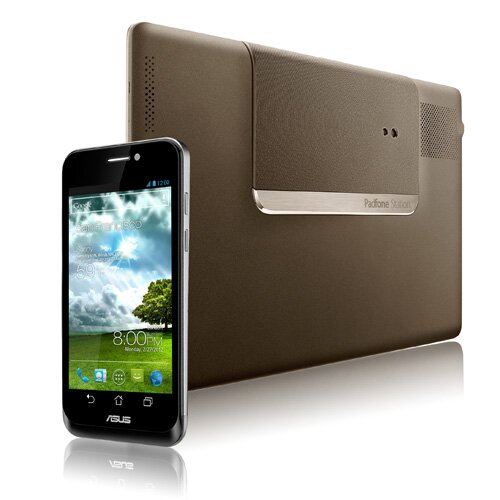

As of writing this article very few commercial OLED TVs and monitors exist, and all are prohibitively expensive. OLED technology, however, has become quite popular on mobile devices such as smartphones and tablets where the improved energy efficiency and better image quality compared to LCD technology are major pluses. The small sizes of screens offered by these devices makes OLED technology more viable in terms of price-point, resulting in greater appeal to customers.

The thin and nearly energy-neutral nature of OLED technology has led to research into screens that can be folded/bent like paper, as well as transparent displays. There are even projects aiming to create OLEDs you could wear, and they are perfect for heads up displays in vehicles such as cars and aircraft.

While we already have some amazing monitors out there that offer spectacular image quality, it looks like the future is indeed in OLED, especially with 4K resolutions such as 4096 x 2160 sure to become a commonplace reality within five years.

For more details on OLED technology, you can check www.oled-info.com.

Suds McSoapdish

Thirty years ago, toddler Suds got his first taste of just how enjoyable technology can be when his parents gave him an Atari 2600. He soon picked up on the wonders of the Commodore 64, and the rest is history in the form of a long list of consoles, 80’s home computers and PCs built and assembled with great fervor. Writing and technology gradually moved up from hobbies to professions as Suds became the man he is today, and although he’s worked and traveled the world and experienced many things, technology, especially computing and gaming, has remained a solid constant.